Affordable IT

We provide competitively priced custom software solutions to small and medium sized companies – specialising in business processes automation, factory floor automation, ERP customisations and Cognitive Services (AI).

We provide competitively priced custom software solutions to small and medium sized companies – specialising in business processes automation, factory floor automation, ERP customisations and Cognitive Services (AI).

FourQuant provides custom software solutions to small and medium sized companies - services that would often be unaffordable if they were procured from less agile, more traditional IT consultancies.

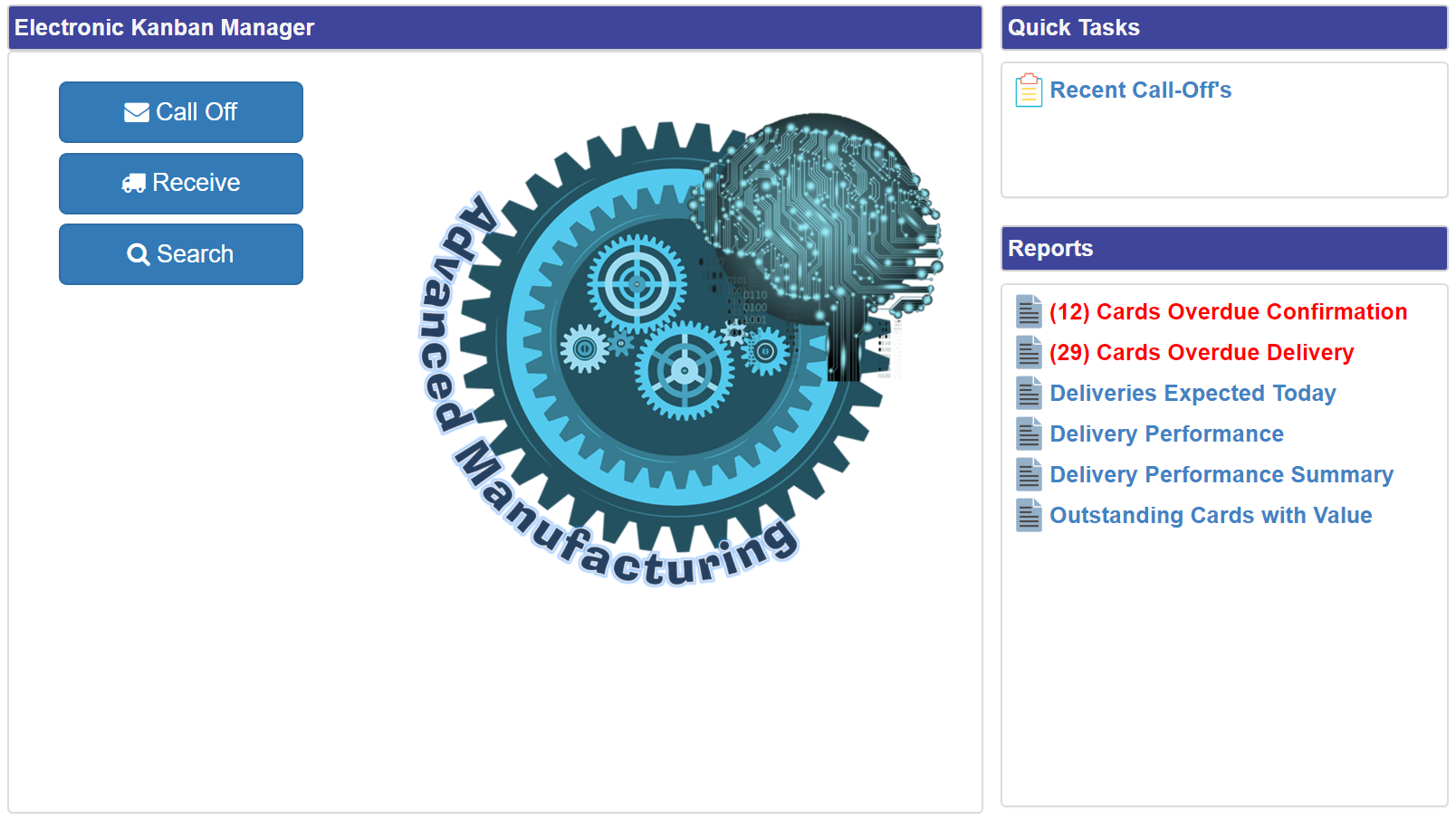

An e-PO’s system that can be plugged into your ERP/Enterprise system to achieve maximum automation of materials procurement from Suppliers.

Full integration with your Enterprise system can be achieved, such as EDI or pulling in production schedule and component demand details to automate Purchase Order Change request approvals.

Additional customisation options available based on your ERP system and business needs.

Securly expose Purchasing requirements to your Suppliers and eliminate manual handling of Purchase Orders.

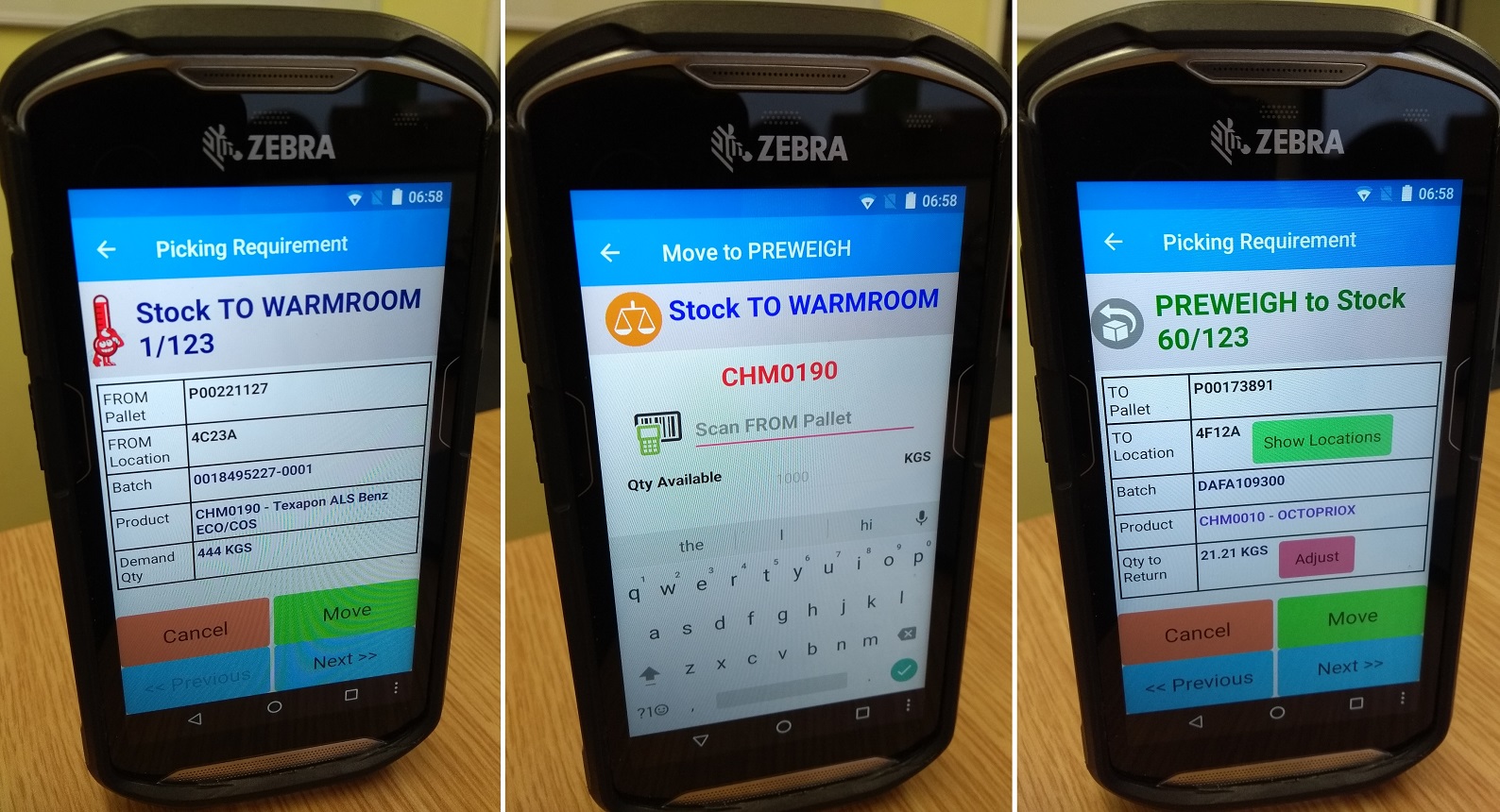

Inventory Management from factory floor with mobile devices.

FourQuant designed and implemented mobile applications that drive Inventory processes in the warehouse and on the factory floor at a leading British cosmetics manufacturer.

The application can run on any Android or iOS device in any form factor, from a mobile phone to rugged mobile computers.

The applications communicate with in-house ERP systems via secure Web API’s written by FourQuant in the latest .NET Core standard.

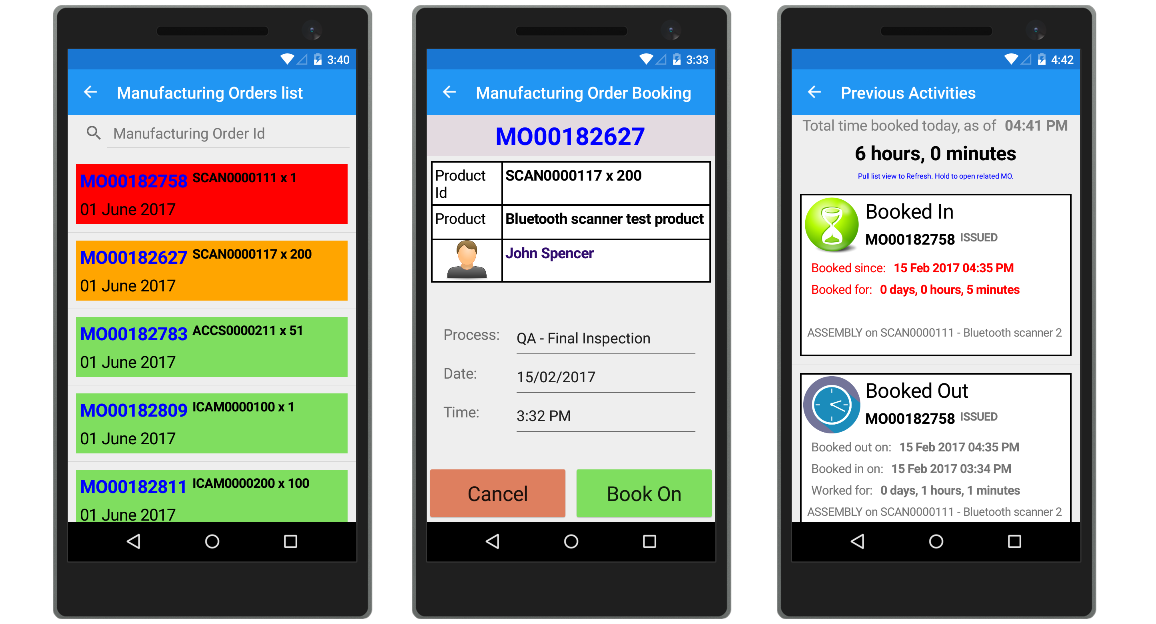

ERP control from factory floor with mobile devices.

FourQuant created and implemented a mobile application that let a leading British electronics designer and manufacturer record labour transactions from the factory floor.

The application allows shopfloor staff to select which manufacturing orders they are working on, which led to more accurate costing of the labour component of manufacturing processes.

Fully ERP-integrated and cross-platform (iOS, Android and Windows) the application improved data accuracy, with the system self-managing with push notifications.

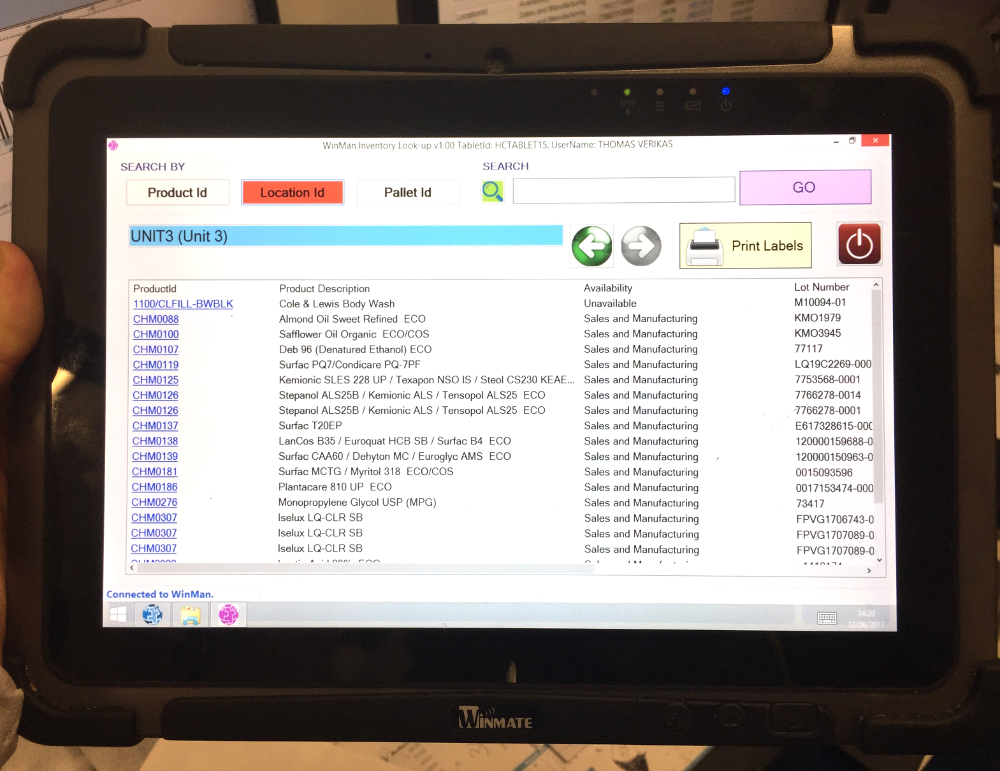

We created a bespoke shop floor inventory management application for a major British cosmetics manufacturer.

The application is installed on factory floor tablets and used to retrieve detailed inventory data and print product labels.

Fully ERP-integrated and with intuitive and practical user interface, the application enabled real-time inventory status retrieval, such as available quantities, stock locations or inventory pallet ID’s.

The application is also used to print different label types (laboratory labels, pallet labels, etc.) on printers allocated to specific manufacturing areas.

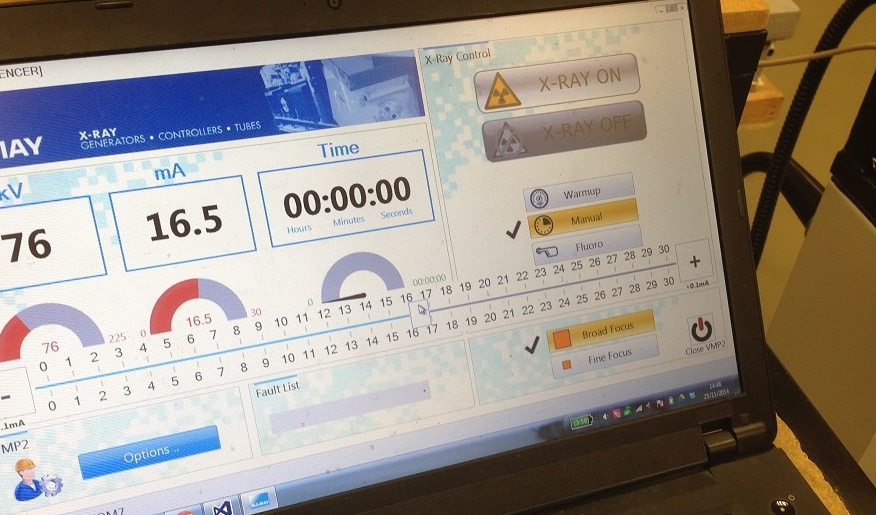

We designed and wrote a desktop application for a major British X-Rays generators manufacturer.

The Windows application allows users to control X-Ray generators from within a computerized environment.

The application allows users to define operating parameters for radiographic exposure such as the X-Ray tube kV settings, mA setting and exposure duration as well as generating X-Rays in constant source mode so that fluoroscopic inspection can be accomplished while using real-time equipment.

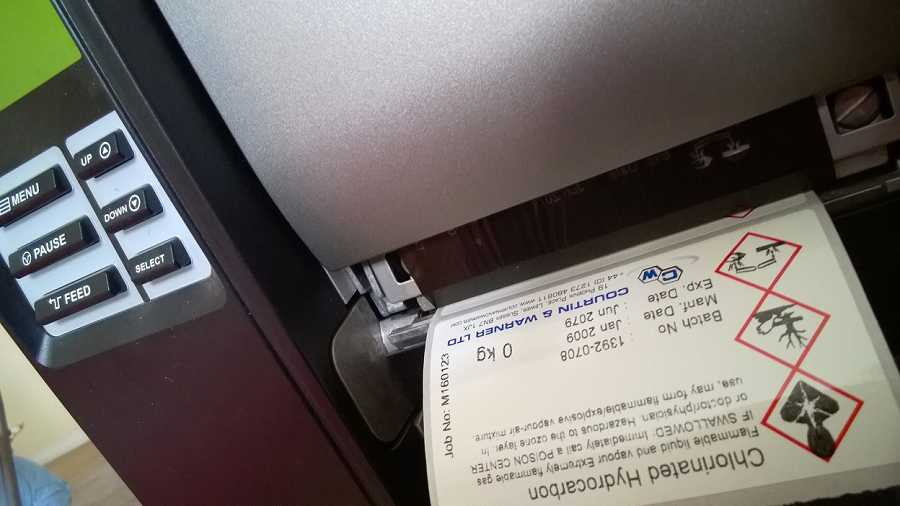

We created an ERP plug-in for automation of printing GHS labels (international standard of labelling hazardous chemicals) for a British pharmaceutical company.

The plug-in is integrated with the manufacturer’s in-house ERP software and retrieves manufacturing order details, such as batch and serial numbers, and generates GHS-compliant labels which are sent for batch printing on the shop floor.

The plug-in allows easy GHS label configuration per product through an intuitive user interface - accessible directly from client’s ERP software.

To guarantee projects long term scalability, support and maintainability, we only use the latest technologies. We offer expertise in the cross-platform .NET Core stack, including: